In case of emergency, part of the new World Trade Center will be powered by the Bronx.

Hunt Point’s A L Eastmond and Sons, or EASCO, installed six oil tanks earlier this year in three buildings in the complex, which began reconstruction in 2008 and is slated to house thousands of workers within the next year.

Ideally, the tanks will never be used. But if the lights go out, or another Hurricane storms into town, the Bronx-made steel fuel sources will be ready to keep the massive buildings running.

“The first boilers that we built as a manufacturer are still in use 25 years later, running as we speak,” said Leon Eastmond, the company’s president. “We only make quality products.”

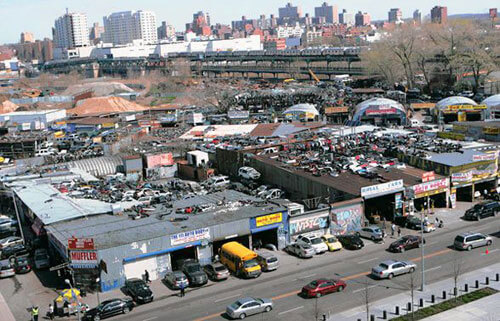

EASCO opened up shop in a cavernous Hunt’s Point warehouse on Tiffany Street in 1974, but the company has been making boilers and tanks for nearly 90 years in various iterations.

Eastmond inherited the business from his father, who first repaired boilers, then organized groups of workers to craft the steel machines from scratch.

Now EASCO is one of the major players in the New York boiler scene, and is the only black-owned boiler and tank maker in the City.

The new World Trade Center is not the company’s first high-profile job —EASCO has installed boilers in the new Yankee Stadium and at National Geographic headquarters in Washington, D.C.

But the symbolism of being at the heart of the new World Trade Center, 12 years after the Twin Towers were destroyed, is not lost on the manufacturer.

“These size contracts come across our table frequently enough, but to be part of this, as a New York company, it’s special,” said Tyren Eastmond, Leon’s grandson, current chief operating officer and the company’s heir apparent.

EASCO landed the original contract for the tanks in 2005, but the developers decided to replace them after Superstorm Sandy caused minor saltwater damage to the machines, said Neil Tomasetti, director of boiler repair and tank sales.

The tanks installed this year are replacements and were crafted in two months in the Hunt’s Point warehouse. EASCO’s workers rolled flat sheets of steel to the architect’s specifications and delivered the finished product to the construction site, where gaps were carved into the walls to make room for the tanks.

EASCO is responsible for three 8,000-gallon tanks in 4 World Trade Center, a 72-story, 977-foot building expected to open this fall and house offices for the Port Authority. Two more 8,000-gallon tanks are installed in the basement of a transportation hub that will connected 13 subway lines and serve 250,000 travelers a day at its opening in 2015, developers told the Associated Press in September. The other tank is a 15,000-gallon machine in a planned 80-story office building at 3 World Trade Center.

Not bad for a Bronx-based family business.

“You don’t want to be too bragadocious,” said Leon Eastman, “but our boilers are as good as any, and better than many.